A View from the Cellar

A Crash Course in Cellarmanship Pt. IV

The first three parts of this series were about the history and use of casks. Part Four is about Beer Engines.

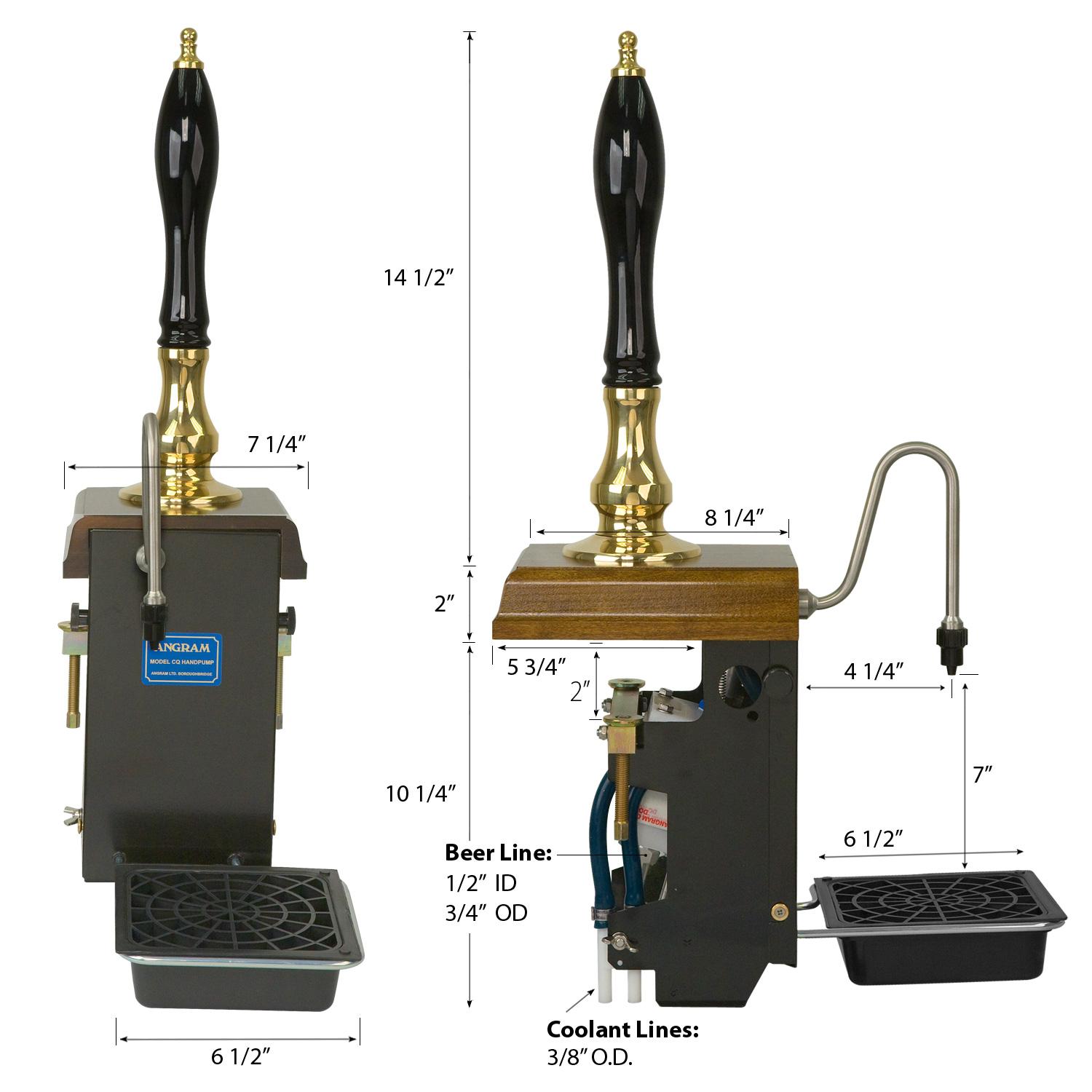

A beer engine, also known as a hand-pump, is the ideal way of serving a cask. Gravity taps can do in a pinch or at a festival, but if you’re serious about casks an engine is essential. Hand pumps do not use any CO2 or Nitrogen to push the beer; they have a small tank at the back and a valve which draws the beer directly from the cask. They are very low tech and are pretty easy to set up and use, with no electronics and very little plumbing.

The engine should be mounted on a table or bar using the vise grips at the back. Sometimes they can be built into the bar. The line should be as short as practically possible and, if possible, quite wide using a braided hose – regular hose tends to collapse under the vacuum of the pull and can lead to CO2 separation. Regular beer lines are quite narrow so that the beer can be transported by gas pressure over long distances. I use wide-gauge hose so that the pull is easy, the beer doesn’t warm up as quickly due to the lower surface area/volume ratio. Most engines come in either half- or quarter-pint pulls – that is to say one pull should pump about 500ml or 250ml. I prefer half-pint pulls as they fill a pint glass quickly and smoothly. The cask must be stored below the engine otherwise the entire cask will siphon out, hence the use of a cellar for storing casks rather than balancing them on top of a bar in a hot pub.

Some engines have a cooling jacket around the tank which can have water or glycol circulating, keeping the beer chilled in the pump, This is worth considering if you would like your beer kept colder or if there are long gaps between uses.

To pour the perfect pint put the end of the nozzle as close to the bottom of the glass as possible, then slowly start the pour. Once the head has been submerged beneath the beer, you should pull a little bit faster. Keep the nozzle head at the bottom of the glass all the way. Once the glass is full, set it on the drip tray and wait for it to settle; this will reveal how much of the beer is head. When ready, put the nozzle back into the beer and slowly top it up; if the foam runs over the side, it’s no problem. Leave a good-sized head but no more than ½” to ¾”. If you receive more head than that, please send it back for a top up – anywhere that takes cask beer seriously will happily do this for you.

“Can I have a flake for that please?” [note: UK humour. Meaning: ‘this beer looks like an ice cream’]

Often the end of the swan-neck will have what is known as a “sparkler”; this small plastic screw-on shower head is the subject of much discussion in the UK. Commonly used in the north of England and Scotland but less so in the South, it acts a little like an aerator. The beer is pushed through many tiny holes; this pushes the CO2 out of solution creating that beautiful nitro-style cascade, creamy body and lasting head that is characteristic of a well poured pint of real ale. In fact the Nitro system pioneered by Guinness was an attempt to artificially recreate this natural effect from a keg beer.

The downside of the sparkler is that the overall carbonation is reduced and hop aroma can be reduced, so it’s very much a personal taste. It is interesting how different the same beer can taste when poured through a sparkler or not – try it!. At the end of service the sparklers should be removed and put into a glass of soda water overnight to be kept clean, and run through a glass-washer as often as convenient.

Beer lines should be cleaned every 2-3 weeks but cask lines benefit from more frequent cleaning, usually 1-2 weeks. This is because there is comparatively more organic material travelling through the line, which can build up in the line and engine. A lighter cleaning agent used more frequently is preferred because there are delicate parts of the engine which can be damaged by harsher abrasives. More on line cleaning in a few issues time.

Pump clips are the small shields that are affixed to the pump handle so that customers can easily see which beer is on which pump – similar to the way that tap handles are used by breweries to advertise. These clips don’t get used often in North America as there’s rarely more than one cask on at a time, but these are considered collectable artworks that go missing from pubs in the UK frequently.

Our final cask masterclass in the next issue will focus on troubleshooting the many things that can go wrong.

If you have any feedback on this series or would like more information please contact me at ac.ksaclaer@mada.

This Post Has 0 Comments